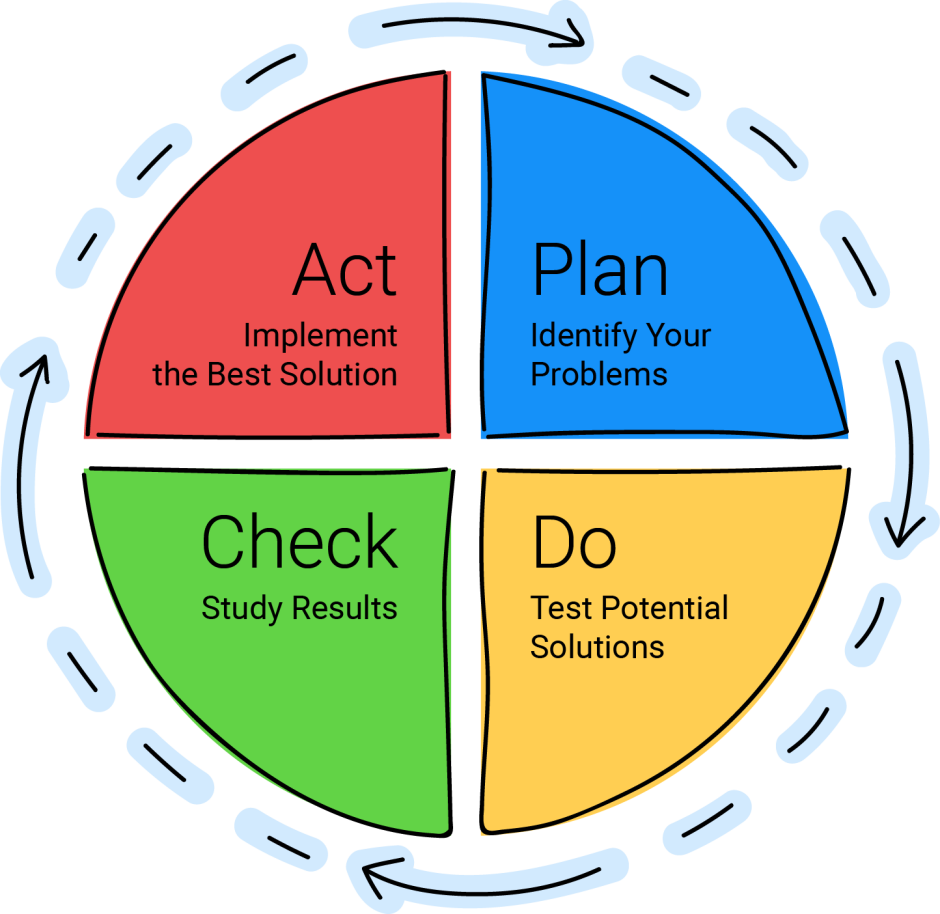

Pdca cycle

The PDCA (Plan-Do-Check-Act) Cycle, also known as the Deming Cycle, is a systematic approach that helps organizations improve their processes and achieve continuous improvement. This powerful tool encompasses four stages: planning, execution, evaluation, and adjustment.

In the planning phase, organizations set clear goals and objectives. They identify the problem or opportunity for improvement and develop a detailed plan to address it. This includes defining specific actions, allocating resources, and establishing timelines.

Once the plan is in place, the organization moves into the "do" phase where they execute the planned actions. This involves implementing the changes, collecting data, and monitoring the process closely. It is crucial to follow the plan precisely to ensure accurate evaluation later on.

The "check" phase is all about evaluating the results obtained from the execution phase. Organizations collect and analyze data to determine whether the implemented changes have had the desired effect. This step helps to identify any deviations or issues that need to be addressed.

Based on the findings from the evaluation, the organization proceeds to the "act" phase. Here, they make necessary adjustments and improvements to the process based on the data collected. This may involve modifying the original plan, changing resource allocation, or adopting new strategies to further enhance performance.

The PDCA cycle is not a one-time process but rather a continuous loop of improvement. After completing one cycle, organizations repeat the entire process, incorporating lessons learned and feedback received. This iterative approach ensures that organizations are constantly refining and optimizing their processes to achieve better results.

In conclusion, the PDCA cycle is a proven methodology that empowers organizations to systematically analyze, improve, and optimize their processes. By following this structured approach, businesses can drive continuous improvement, enhance efficiency, and ultimately achieve their goals.